Our client is a UK-based aviation spares distributor supporting 120+ airlines and MRO facilities globally. The company supplies safety-critical components for commercial and private aircraft, including fast-moving engine spares and specialized avionics. Their catalog includes thousands of parts managed across a broad logistics footprint.

The client’s service teams were under strain due to delivery delays, unreliable stock visibility, and an escalating volume of inbound requests from airline maintenance teams.

They wanted an intelligent system that could:

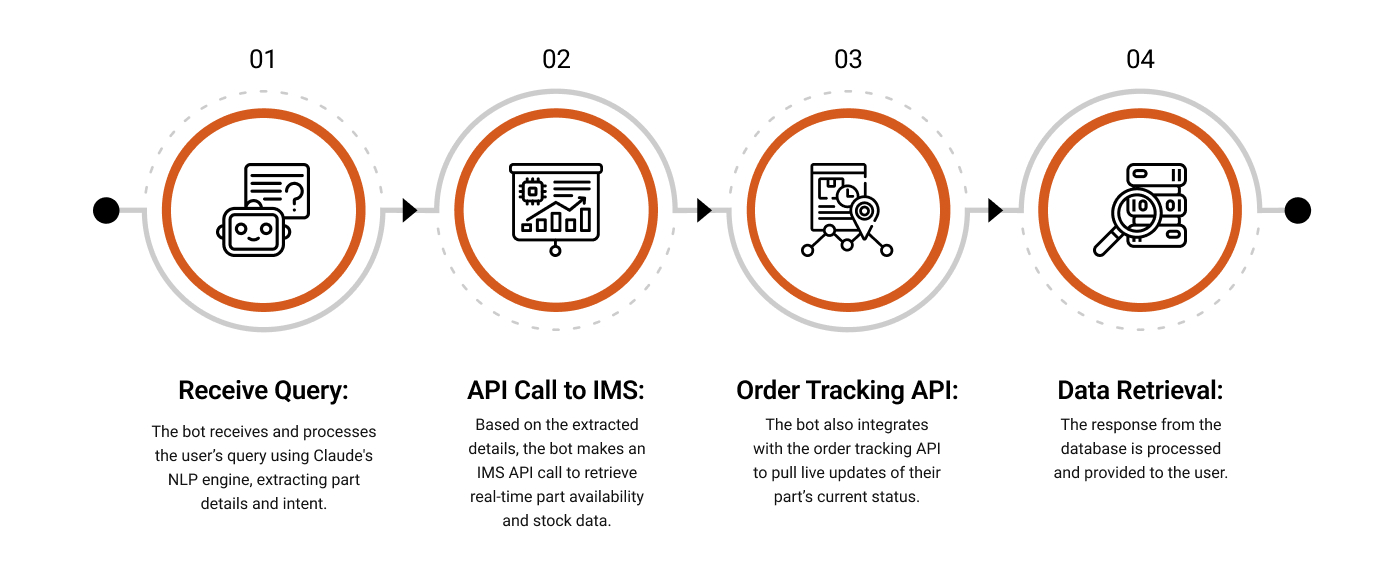

We delivered a multi-channel AI assistant powered by Claude 3.5 Sonnet, integrated with the client’s CRM, inventory platform, and order tracking stack. The bot reduced repetitive support work while improving the speed and consistency of inventory lookups and customer responses.

How the GPT-Bot was Developed

We worked closely with their operations and customer support teams to isolate high-frequency request types and escalation triggers.

We chose Claude 3.5 Sonnet for strong intent recognition and multi-turn conversation handling.

We designed a scalable, service-based architecture to ensure the virtual agent could scale.

We stress-tested the bot to confirm it remained responsive during peak maintenance periods and validated performance at up to 1,100 inquiries per day, with no noticeable latency or stability issues.

To continuously improve accuracy, we implemented a structured feedback loop:

The architecture was designed to support an upgrade to Agentic AI, enabling the assistant to move from simply answering questions to executing approved workflows autonomously for:

Auto-create restock requests when inventory falls below defined thresholds, with approval routing to the right teams.

Initiate pick, pack, and dispatch steps for eligible replacement parts once availability and SLAs are confirmed.

Prepare draft orders for airline maintenance teams based on historic purchase patterns, approved part lists, and compatibility rules, then submit only after authorization.

Flag anomalies such as repeated stockouts, delayed shipments, or high-demand parts, and recommend actions to reduce downtime.

55% reduction in routine support calls within 4 months of deployment

35% faster response times for part requests and availability checks.

99% sourcing accuracy in inventory checks and order tracking